Keywordscotyledon demand market microgreens restaurant segment yield

JEL Classification M10, O31, O32, Q10, M31

Full Article

1. Introduction

Microgreens began appearing on the chef’s menus in San Francisco, California, United States, in the early 1980s (USDA, 2014). Although interest in microgreens has expanded since their introduction into high-end culinary establishments in the late 1990’s, the main market continues to be restaurant chefs. Other direct market opportunities could include upscale or gourmet grocery stores, as well as health food stores (Kaiser and Ernst, 2018).

In the last decade Hermosillo’s restaurant industry, located in the central area of the state, has grown considerably; since one of the main social attractions for both, the citizens and tourists, are the restaurants. According to observations made in the Hermosillo’s restaurant industry, there is an unknown demand for microgreens, which has begun to be satisfied by neighboring or nearby states of Mexico.

Microgreens that are introduced by some gourmet restaurants in the city of Hermosillo, do it by air or land transportation. At the moment they cut, packed and shipped, they only have one or two days of shelf life, so this process has a high cost and they are highly perishable. The investigation is oriented to demonstrate the productive viability of microgreens, as an alternative horticultural production within the urban area of Hermosillo, in small scale area and under controlled environment. The beneficiaries of this investigation are directly people interested in the induction and production of microgreens for those who seek to innovate the gastronomic industry and produce through an alternative system of horticultural production.

2. Literature Review

Sprouts, microgreens and edible flowers constitute a growing segment of the market in developed countries, where restaurant chefs use these parts of plants to add exotic flavors, colors, and creative presentations to the dishes offered to health conscious consumers (Andreas, 2012). They can also be considered an innovation of the concept of vegetable industry, as, for example, the products of IV and V range or the systems of production without soil. These are the innovations that contribute to transform the whole concept of agriculture (Di Gioia and Santamaria, 2014).

2.1. Crop Characteristics

Microgreens provide exceptional flavors, a profile of great nutritional value, texture and color. Smaller then baby leaves, and harvested later than sprouts, microgreens provide a variety of flavors in their leaves, like sweet and spicy, and come with many vibrant colors. The most common are describe below (Di Gioia and Santamaria, 2014):

- Mustard (Brassica juncea var. Red Giant) is characterized by the spicy flavor typical of Brassicaceae due to the presence of glucosinolates (anti-cancer sulfur compounds par excellence) and cotyledons normally heart-shaped, initially green with shades of deep red, growth becoming clearer of the cotyledons. The true leaves, finer and of a different form to that of the cotyledons, are pale green with light red streaks (Di Gioia and Santamaria, 2014).

- Arugula (Eruca Sativa) are generally small in size, characterized by a thin stem, heart-shaped cotyledons, typical of the Brassicaceae, and dark green, while the true leaves are elongated in shape and with margins irregularly mated. The flavor is generally less intense than that of the arugula collected in the baby leaf stage, slightly spicy and typical of the Brassicaceae (Di Gioia and Santamaria, 2014).

- Scallion (Allium fistulosum) is characterized by the smell and taste typical of scallions. Tender cotyledon often keep the husks of the seeds at the apex, as if each cotyledon had an elegant hat. If the cutting of the seedlings is done at a higher height, the scallion is one of the few species of microgreens that can provide more crop of the same plant (Di Gioia and Santamaria, 2014).

2.2. Nutritional Information

Studies conducted by the University of Maryland in 2013 show that different microgreens provide extremely variable amounts of phytonutrients. Compared to the mature leaves of the nutritional concentrations registered in the USDA nutritional database, the cotyledons of microgreens have a higher nutritional density (Xiao et al., 2013).

- Vitamin K1. According to the USDA nutritional database (2011) concentrations of phylloquinone, also known as vitamin K1 in the mature edible parts of amaranth, basil and red cabbage were 1.14, 0.41, and 0.04 μg/g of fresh weight (FW), respectively, which was much lower than their corresponding microgreens (4.09, 3.20 and 2.77 μg/g FW, respectively). Four of the 26 varieties of microgreens analyzed had a comparable amount of phylloquinone to mature leaf spinach, which is generally considered an excellent source of vitamin K1, demonstrating that most of the 26 microgreens species can serve as a good natural source of vitamin K1 (Xiao et al., 2013).

- Vitamin C. The 26 varieties exhibited a total ascorbic acid concentration of 20.4 to 147.0 mg/100 g FW. Vitamin C contained in purple cabbage microgreens (147.0 mg/100 g FW) was 6 times higher than data from past publications of a mature purple cabbage (24.4 mg/100g FW) (Singh, 2006) and 2.6 times higher (57.0 mg/100 g FW) registered in the USDA nutritional database for standard reference (USDA, 2011), and was determined to be 24 times higher than the estimated average ascorbic acid requirement (vitamin C). Therefore, it was suggested that fresh microgreens are generally good to excellent source of ascorbic acid (vitamin c) and probably more concentrated with total ascorbic acid than their mature plant counterparts (Xiao et al., 2013).

- Provitamin A. Among the microgreens studied, red sorrel, had the highest concentration of β-carotene (12.1mg/100 g FW), followed by cilantro, purple cabbage and peppercress (11.7, 11.5 and 11.1 mg/100 g FW respectively). Compared with mature and fully developed cilantro leaves, cilantro microgreens contain 3 times more β-carotene. Purple cabbage contains an average of 11.5 mg/100 g FW that is approximately 260 times more than the value (0.44 mg/100 g FW) reported for mature purple cabbage. In summary, all tested microgreens can be considered as an excellent source of β-carotene, with exception of green and yellow corn shoots (Xiao et al., 2013).

- Carotenoids. While the 26 microgreens analyzed in the study contained lutein and zeaxanthin (carotenoids), cilantro had the highest level of lutein/zeaxanthin with 10.1 mg/100 mg FW. Microgreens of red sorrel, purple cabbage and amaranth followed with concentrations of 8.8, 8.6 and 8.4 mg/100 g FW, respectively. These values were higher than those of mature spinach (7.2 mg/100 g FW), which contains high values of lutein/zeaxatin (Xiao et al., 2013).

- Vitamin E. Radish “daikon” has extremely high contents of α-tocopherol and γ-tocopherol of 87.4 mg/100 g FW. In addition, cilantro microgreens, radish “opal” and peppercress are also excellent sources of α-tocopherol and γ-tocopherol, with concentrations of α-tocopherol from 41.2 to 53.1 mg/100 g FW, and values of γ-tocopherol from 12.5 to 16.7 mg/100 g FW. Purple cabbage microgreens contain vitamin E more than 40 times than in its mature counterpart (0.06 mg/100 g FW) (Xiao et al., 2013).

2.3. Production Technology

Microgreens are generally produced with soilless cropping systems, that are, systems which the soil is replaced by a substrate or a liquid medium. The production of microgreens can take place in different environments and be carried out commercially, using advanced techniques necessary to guarantee the continuity of production and good product quality, or at a non-professional level, for self-consumption, using very simple means and techniques and also very small places, like a window (Di Gioia and Santamaria, 2014). The species of vegetables most commonly used for the production of microgreens belong to different botanical families, including Brassicaceae (for example, cauliflower, broccoli, cabbage, kale, watercress, mizuna, radish, arugula and mustard), Asteraceae (for example, lettuce, escarole, common chicory, radicchio), Apiaceae (dill, carrot, fennel, celery), Amaryllidaceae (garlic, onion, leek), Amaranthaceae (amaranth, chard, beet, spinach) and Cucurbitaceae (melon, cucumber, pumpkin). It is very important to pay attention to the choice of species that will be destined for the production of microgreens, carefully evaluating the edibility of each species in the seedling stage. Some species of vegetables, for example, the Solanaceae family, such as tomatoes, pepper and eggplant, which in the seedling phase can have a high antinutrient content and are therefore considered inedible (Di Gioia and Santamaria, 2014).

From the agronomic and commercial point of view the choice of the species that can be grown to produce microgreens is closely linked to the availability of quality seeds, which are characterized by a high and homogeneous germination, not chemically treated, hygienically safe and at the same time available at low cost. In addition, it is very important to choose species that are cultivable throughout the year and that do not have particular thermal requirements especially during the germination phase. Finally, a critical aspect at commercial level is the post-harvest duration of the product (Di Gioia and Santamaria, 2014).

2.4. International and National Demand

Currently, there are no microgreens consumption databases. But nevertheless, several sources (from universities, journals and blogs) mention the growing demand that this product has had in recent years around the world.

- In 2012, Adriana Gutierrez (2012) of the Department of Horticulture of the Virginia College of Agriculture and Biological Sciences mentions “During the last 10 years, the demand for microgreens has expanded dramatically, moving from high-end restaurants to “mainstream” white tablecloth restaurants.”

- Cheryl Kasier and Matt Ernest (2012) of the University of Kentucky say “Promoted as a highly nutritious food product, the demand for microgreens has increased since they were identified as national trend in the high kitchen around 2006. Many white tablecloth restaurants now incorporated microgreens as garnish or flavoring.

- The company Hydrophoria of the United Kingdom has been quick to sell thanks to the high demand for its unique offer of hydroponic microgreens (McShane, 2015).

- An Israeli company called 2B Fresh in 2012 doubled its productive capacity of microgreens and mention “It’s almost unlimited, it’s not a problem for us provide a great demand” (de Nijs, 2013).

- In Mexico, the National Restaurant Association released a list of the main food and beverage trends for the year 2009, the survey was applied to more than 1,600 chefs resulting the microgreens being placed in the 5th place in the product category, marking the great growth and demand for these within the high cuisine segment (Gusto Buen Vivr, 2012).

2.5. International and National Offer

As well as the demand, there in not a concentration of international data nor national studies about total microgreens production. However, in social networks and internet sources, farms are promoted, which are dabbling with this new crop, opening new markets and growing more and more, demonstrating the importance of urban agriculture.

- Urban Produce Microgreens (California, USA) is an urban vertical farm that specializes in the organic production of live microgreens, wheatgrass and baby leaves.

- MicroFerma (Moscow, Russia) is small warm farm. Grow for restaurants, cafes and vegetable-based super markets in Moscow and work in a system of pre-orders.

- 2B Fresh (Olesh, Israel) is a leader in the Israeli microgreens market. Their products are exported to the following countries: United Kingdom, Germany, France, Poland, Czech Republic, Russia, Switzerland, Hong Kong and USA.

- Sky Harvest (Vancouver, Canada) grows microgreens and baby leaves high quality organic to restaurants and retail in Vancouver.

- Microfarms (Nuevo Leon, Mexico) produce fresh shoots and microgreens under greenhouse conditions, selling to hotels and restaurants.

- Alfavid (Baja California, Mexico) produce microgreens and sprouts for hotels, restaurants and local markets.

2.6. Prices

The price of microgreens will be different depending on the area where they are being produced. This is due to several factors that vary in the costs and production time of different species. Different species of microgreens seeds will have a different germination rate. In addition, different types of seeds can have a very different price. For example, it is $ 15 USD for each pound of parsley seeds but $ 45 USD for basil seeds and $ 350 USD for marigold seeds. Water and electricity are a variable cost in the different seasons of the year. The average sale price for microgreens in the United States is $ 25 USD - $ 40 USD per pound (MicroVeggy, 2019).

On the other hand, in Mexico, where there is no access to seeds free of synthetic chemicals for the production of microgreens, import costs of seeds have to be considered. This makes prices nationwide higher. Prices in Mexico vary considerably as shown in table 1 and 2.

Table 1. Microgreens prices in MXN per gram in Microfarms, Nuevo León, Mexico.

|

Microgreens Species |

Price (MXN)/Gram |

|

Beet |

$9 |

|

Amaranth |

$9 |

|

Cilantro |

$4 |

|

Pea |

$6 |

|

Scallion |

$9 |

|

Arugula |

$9 |

|

Basil |

$9 |

|

Radish |

$9 |

Source: own, from Microfarms (2017).

Table 2.Microgreens price in MXN per gram in Playerbas, Quintana Roo, Mexico.

|

Microgreens Species |

Price (MXN)/Gram |

|

Beet |

$4 |

|

Amaranth |

$4 |

|

Cilantro |

$4 |

|

Pea |

$4 |

|

Scallion |

$4 |

|

Arugula |

$4 |

|

Basil |

$4 |

|

Radish |

$4 |

Source: own, from Playerbas, (2017).

Table 3. Microgreens prices in MXN per gram in New Natives, California, EUA.

|

Microgreens species |

Price (MXN)/Gram |

|

Pea |

$0.80 |

|

Broccoli |

$1.16 |

|

Arugula |

$1.30 |

|

Radish |

0.98 |

|

Wheatgrass |

0.45 |

|

Mix |

1.16 |

Source: own, from goodeggs (2017).

2.7. Market Segments

At a national and international level, the microgreens market segment corresponds to high cuisine restaurants. In developed countries the market segments are expanded to organic supermarkets and local markets (farmers market) where the population is willing to pay a high price to obtain good quality, organic, local and nutritious products.

2.8. Commercial and Distribution Channels

In the international and national scope, microgreens companies offer this product through marketing channels of different levels:

Level 1. Producer > Consumer

Level 2. Producer > Restaurant > Consumer

Level 3. Producer > Super market > Consumer

3. Research Methodology

3.1. Microgreens Production

- Establishment of the system. The vertical system consisted of a mobile chromed steel shelve (Whitmor brand) with dimensions of 36 cm wide, 77 cm long, 153 cm high and four levels. In each level, LED ceiling luminaries of 63 cm length and 14 watts, were placed.

Photo 1. Production shelf

Source: own (2017).

Photo 2. Artificial lighting LED 14 Watts.

Source: own (2017).

- Seed selection. Due to the availability of seeds without chemical treatment in Mexico, the selected varieties were: mustard (Brassica juncea), amaranth (Amaranthus tricolor), radish (Raphanus sativus) and arugula (Eruca Sativa), which were acquired from two different suppliers. One of them was “La Semilleria”, located in the state of Queretaro and the other was Microgreens Mexico, located in Mexico City. The selection of these providers was be the characteristics required for the seeds that are used for the production of microgreens.

Photo 3. Moistening the mix substrate PROMIX.

Photo 4. Substrate placed in sowing trays.

Source: own (2017).

- Substrate preparation and sowing. Once the production system was established and the seeds were selected, planting began on April 13, 2017. To begin the planting, 8 sowing trays with drainage holes (12.7 cm x 12.7 cm x 6 cm) were first placed over one irrigation tray (50.8 cm x 25.4 cm x 6 cm); a total of 32 sowing trays were placed in 8 irrigation trays. Then, PROMIX (substrate mix) was moistened and 3 cm high height was placed in each sowing tray. Subsequently the planting densities were weighed on a digital kitchen weight for each species as shown in table 4.

Table 4. Densities of seeds per species placed in each sowing tray.

|

Species |

Density (grams)/sowing tray |

|

Mustard (Brassica juncea) |

3 |

|

Amaranth (Amaranthus tricolor) |

3 |

|

Radish (Raphanus sativus L.) |

5 |

|

Arugula (Eruca sativa L.) |

3 |

Source: own.

Photo 5. Measuring densities of seeds.

Photo 6. Placing seeds in each sowing tray.

Source: own (2017).

Once there densities were weighed, the seeds were scattered on the surface of the substrate of each sowing tray evenly, they were sprayed evenly and the irrigation trays were placed in each level of the shelf.

Photo 7. Spraying the seeds.

Photo 8. Darkness for promoting germination.

Source: own (2017).

- Maintenance. To obtain a successful germination uniformity, the temperature was maintained in a range of 20-25°C (monitoring a thermometer). Each tray were sprayed every time the substrate change to a lighter color. Once each species germinated, the trays on the top that were giving darkness to the seeds were removed and the luminaries started to be on daily for 12 hours. Also, when the seeds germinated the irrigation was change to sub irrigation (letting the holes of the sowing tray absorb the water from the irrigation tray) to avoid excess moisture on the surface.

Photo 9. Day 3 of arugula (Eruca sativa). First day of lighting.

Source: own (2017).

Photo 10. Day 5 of amaranth (Amaranthus tricolor).

Photo 11. Day 5 of mustard (Brassica juncea).

Source: own (2017).

Photo 12. Day 17 of amaranth (Amaranthus tricolor).

Source: own (2017).

Photo 13. Day 10 of arugula (Eruca sativa).

Source: own (2017).

Photo 14. Day 14 of radish (Raphanus sativus.

Photo 15. Day 12 of mustard (Brassica juncea).

- Harvest. The harvest was based on the maturity index described in the definition of microgreens (complete development of the cotyledons). In order to carry out the harvest, the scissors were first washed and disinfected with iodine (20 ppm, as recommended by the Department of Food Science, Nutrition and Packaging of Clemson University). Each species were harvested, weighed and recorded (yield and days after planting). Microgreens were packed in clam shell containers and store in a domestic refrigerator.

3.2. Market Research

- Zone description. The municipality of Hermosillo, capital of the state of Sonora, is located between 29° 05’ 44’’ north latitude and 110° 57’ 03’’ west longitude and has a total area of 168.2 km2. Hermosillo is the 15th most populous in the country and the number one in growth from 2010 to 2015, reveals the National Institute of Statistics and Geography (INEGI). As of march 2015, it reached a population of 884,273 inhabitants with an annual growth rate average (in the last five years) of 2.8%. According to the National Statistical Directory of Economic Units (DENUE), currently there are 229 establishments offering food and beverage preparation services. However, no all of these establishments meet the characteristics that define our unit of analysis. Therefore, we established the following characteristics to delimit the population of study.

- Management of high cuisine (artistic and elaborated).

- Average price range per customer >200.

- Customer service with waiters.

- They offer alcoholic beverages.

- Closed establishment (with possibility of garden or terrace).

- Population and sample. Based on these characteristics, with observation and investigation of secondary sources (restaurant websites, food critics, “Annual Sonoran Chef Festival Magazine (2017)”, the population was delimited to 60 gourmet restaurants within the city of Hermosillo. Discarding fast food establishments and food trucks.

To apply the surveys in order to know the current and potential demand, a sample was calculated for a population of 60 gourmet restaurants with the following statistical procedure.

![]()

n = size of the sample

k = constant that depends on the level of confidence that we assign. The confidence level indicates the probability that the result of our investigation are true.

p = proportion of restaurants that have the study characteristics unknown and it is usually assumed that p=q=0.5 which is the safest option.

q = proportion of restaurants that do not have that characteristics, that is, it is 1-p.

N= population size.

e = desired sample error.

With a population of 60 gourmet restaurants in Hermosillo (N), with confidence level of 95.5% that determines k= 2, we want a sampling error of 5% (e) and consider that there is a current demand of 50% (p=q=0.5).

![]()

![]()

![]()

![]()

Once the sample size was obtained (52 gourmet restaurants), we continued with the selection of the sample. The selected procedure was by raffle, where we write on a sheet the name of all the gourmet restaurants numbered from 1-60. Later we placed the numbers in a raffle and we randomly extracted 52 numbers which will be the restaurants that will be surveyed.

- Variables and sub-variables.

Offer, current and potential demand: quantity, availability of purchase, price and preferences.

Market segment: type of restaurant and price range per customer.

- Development of instruments. To carry out the market research, a survey was elaborated with questions to address the variables.

- Fieldwork (data collection). This phase was held on April 19, 2018 in “El festival del Chef Sonora” annual festival organized by GANFER Foundation in which all Hermosillo restaurants, suppliers, importers and local producers participate in order to promote and enjoy the cuisine of Mexico’s northwest area. To apply the surveys I presented myself at each stand explaining the purpose of the study and doing a short interview with the questions of the survey.

- Data processing and analysis. This phase consisted in processing the data obtained from the surveys in the software Social Package for the Social Sciences (SPSS), computer statistical program widely used in social and applied sciences, in addition to market research companies. With this program, output tables and cross tabulation were created to consolidate the quantitative and qualitative information.

- Result discussion. The discussion of the information obtained was based on the analysis through the output tables. This discussion was held jointly by the student and thesis committee in order to incorporate the concerns and suggestions to enrich the content of the final document.

4. Analysis and Results

4.1. Microgreens Production

Table 5 explains the microgreens yield and the average days for them to reach maturity.

Table 5. Obtained microgreens yield and average days to maturity..

|

Species |

Avg. seeds/tray (grams) |

Avg. yield/tray (grams) |

Avg. days to maturity |

|

Mustard (Brassica juncea) |

3 |

23.6 |

12 |

|

Amaranth (Amaranthus tricolor) |

3 |

15.6 |

17 |

|

Radish (Raphanus sativus) |

5 |

39.1 |

9 |

|

Arugula (Eruca sativa) |

3 |

21.3 |

14 |

Source: own (2017).

4.2. Market Research

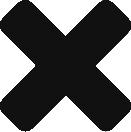

To carry out the survey, a sample of 52 restaurants was taken. 28.8% of restaurants are international cuisine, 26.9% Mexican, 17.3% Mediterranean, 15.4% sea food and 11.5% Asian, as presented in Figure 1.

Figure 1. Type of restaurant

Source: own (2017).

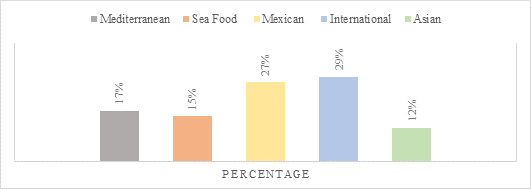

In figure 2, we notice that 5.8% of the restaurants have an average price range per customer of $150-$250, 42.3% $251-$300 and 51.9% $351-$500.

Figure 2. Average price per customer.

Source: own (2017).

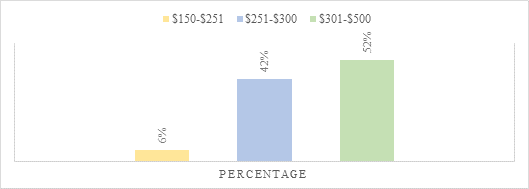

In Figure 3, we observe that microgreens are known for 61.54% of the sample, while 38.46% do not know the Microgreens.

Figure 3. Have you heard of microgreens before?

Source: own (2017).

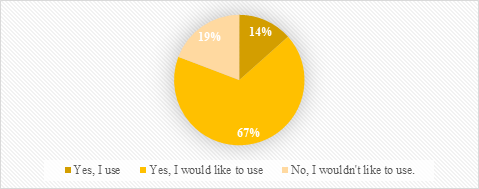

Currently, microgreens are used by 13.46% of the sample, which indicates that there is a real demand for this product in the regional market, while 67.31% of the sample would like to introduce them in their restaurants. However, 19.23% of the sample is not interested in using this product, as presented in Figure 4.

Figure 4. Do you use or would like to use microgreens in the restaurant?

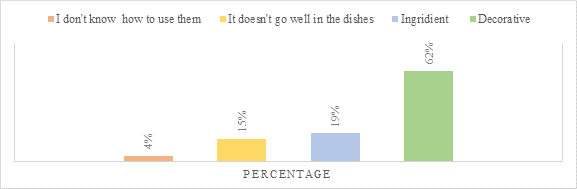

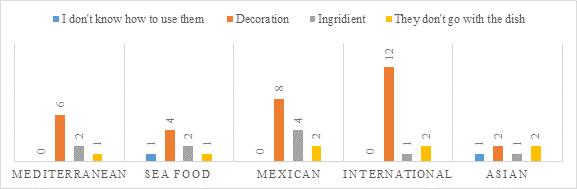

In Figure 5, 61.54% use them or would like to use them to decorate their dishes and 19.23% use them as an ingredient. On the other hand, 15.38% say that they do not go with their dishes and 3.85% have no knowledge of how to use them.

Figure 5. Why would you like or not to use microgreens?

Source: own (2017).

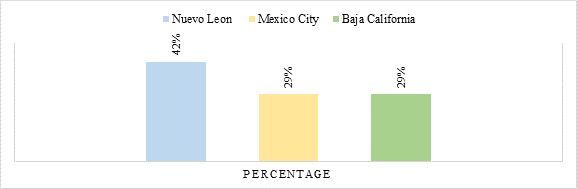

Figure 6 presents the origin of the supplier. Of the 13.46% of the sample that currently uses microgreens in their restaurants, they were asked questions to know the current offer in Hermosillo, prices that are handled in the national market and preferences on the product as species with more demand and presentation of the product. 42.86% of restaurants that use microgreens buy them in the state of Nuevo Leon, 28.57% in Mexico City and the remaining 28.57% in Baja California.

Figure 6. What’s the origin of your supplier?

Source: own (2017).

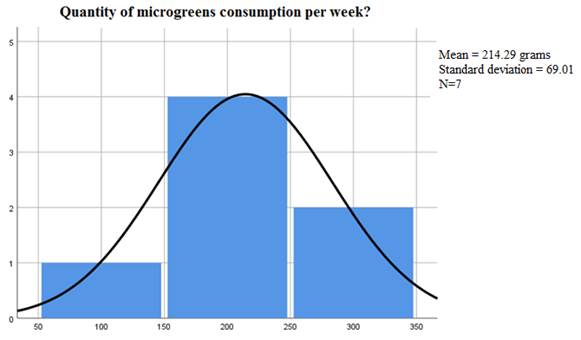

Figure 7 presents the quantity of microgreens consumption per week. The average amount of microgreens that restaurants use weekly is 214.29 grams; considering that the standard deviation is +/- 69.01 grams. This presentation has a mode of 200 grams.

Figure 7. Quantity of microgreens consumption per week

Source: own (2017).

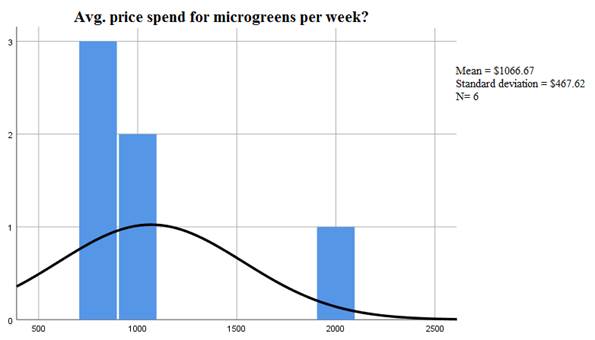

Figure 8 establishes the average price spent for microgreen per week. The average price that restaurants pay weekly for microgreens is $1,066.67; taking into account that the standard deviation is +/- $467.618. This presentation has a mode at the price of $800. In addition, restaurants pay extra for the cost of shipping microgreens.

Figure 8. Average price spent for microgreens per week?

Source: own (2017).

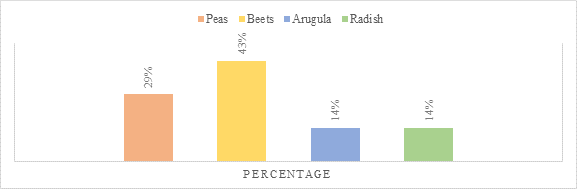

In Figure 9, beet microgreens are the most demanded specie with 42.86% surveyed restaurants that currently use this product. Peas is used by 28.57% of restaurants, arugula by 14.29% and radish by 14.29% of restaurants.

Figure 9. Preferred species?

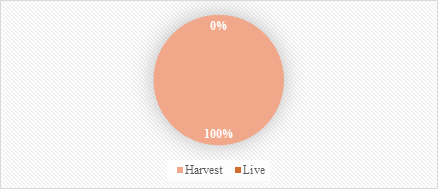

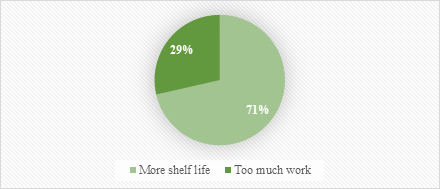

Figure 10 and 11 explore the habit of acquiring microgreens. 100% of the surveyed restaurants that currently use microgreens receive them harvest and packed. At 71.43% of the restaurants surveyed that currently use the microgreens like the presentation already harvested and packed because they don’t want extra work with the care and maintenance; however, 28.57% of the restaurants surveyed that currently use this product would rather to purchase microgreens with the substrate so that they have a longer shelf life in the kitchen.

Figure 10. Do you acquire harvested microgreens or with the substrate?

Figure 11. Why would you like or not to acquire microgreens in the substrate?

Source: own (2017).

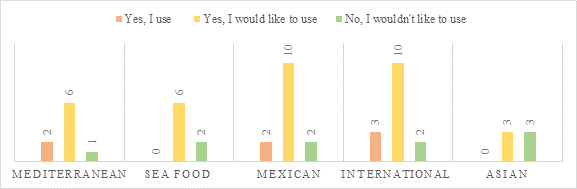

To identify the segment to which the product will be directed, crossing variables were performed, identifying the type of restaurant and average price range per customer. This was done with the objective of getting to know the potential consumers of this product. According to Figure 12, the restaurants that most use microgreens are those of international type of food, followed by the Mexican and Mediterranean. The restaurants with the greatest potential to use microgreens are international and Mexican. Those less interested in using microgreens in their restaurants are the Asian food type.

Figure 12. Relationship “Type of restaurant * Do you use or would like to use microgreens in the restaurant?”

Source: own (2017).

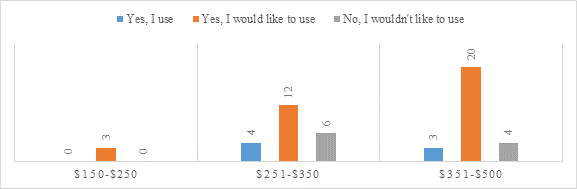

Based on information developed in Figures 13 and 14, the restaurants that have medium price ranges and high of consumption per customer are those currently using microgreens in their dishes. Likewise, all restaurants with medium and high prices that are not currently using microgreens, would like to introduce them to their dishes. However, there are some restaurants with medium and high prices, they wouldn’t like to introduce them.

Figure 13. Relationship “Avg. price per customer * Do you use or would like to use microgreens in the restaurant?”

Figure 12. Relationship “Type of restaurant * Why would you like or not to use microgreens?”

Source: own (2017).

5. Discussion and Conclusion

A large majority of the restaurants surveyed do not know the existence in the national and international market of the microgreens, this is due to the low publicity and presence of the product in the local and national market. The best way to disseminate and demonstrate the use of microgreens in the gastronomic market is to collaborate with chefs and restaurants what currently use this product and share international gastronomic trends on social networks. The 80.77% of the restaurant surveys are willing to use local microgreens which generates a potential demand in the city Hermosillo. The percentage of restaurants that are not willing to use microgreens is because they don’t know their uses or then don’t go in their dishes.

Nowadays more Hermosillo conscious consumers look for alternative healthy and ecological products for the well-being of their families and the environment, that’s why diffusion of microgreens shouldn’t be limited only to the gastronomic industry, but also in the local and naturist markets. Based in the experience gained in the past two years (2018-2017) with Jardin Gourmet, urban farm producing culinary crops in Hermosillo, an important segment was found in the catering and food service industry. It is also recommended to complement the cultivation of microgreens with unique and special crops with the same use, such as edible flowers and aromatic herbs for high cuisine.

References

- Andreas, E., 2012. Sprouts, microgreens, and edible flowers: the potencial for high value specialty produce in Asia. [online] Available at: https://www.researchgate.net/publication/257363587_Sprouts_microgreens_and_edible_flowers_the_potential_for_high_value_specialty_produce_in_Asia [Accessed 11 May 2019].

- de Nijs, B., 2013. Fresh Plaza - Microgreen grower 2BFresh to break open worldwide market. [online] Available at: http://www.freshplaza.com/article/114852/israel-microgreen-grower-2bfresh-to-break-open-worldwide-market [Accessed 11 May 2019].

- Di Gioia , F. and Santamaria , P., 2014. Microgreens; nuevos alimentos frescos y funcionales para explorar todo el valor de la biodiversidad. Milan: Ministero Italiano delle Politiche Agricole Alimentari e Forestali.

- GoodEggs, 2017. Microgreens. [online] Available at: https://www.goodeggs.com/sfbay/search?q=microgreens [Accessed 11 May 2019].

- Gusto Buen Vivir, 2012. Gusto Buen Vivir. [online] Available at: https://gustobuenvivir.com/2012/10/10/todo-lo-que-necesitas-saber-de-microgreens/ [Accessed 11 May 2019].

- Gutierrez, A., 2015. Virgina Tech Department of Horticulture. [online] Available at: http://www.hort.vt.edu/ghvegetables/documents/Leafy%20Greens/Microgreens_Production_with_Sure_to_Grow_Pads.pdf [Accessed 11 May 2019].

- Heritage Prairie Farm Microgreens, 2014. Microgreens: A history Lesson. [online] Available at: http://www.hpfmicrogreens.com [Accessed 11 May 2019].

- Kaiser, C. and Ernst, M., 2012. Microgreens. [online] Available at: https://www.uky.edu/Ag/CCD/introsheets/microgreens.pdf [Accessed 11 May 2019].

- McShane, G., 2015. Produce Business UK - HydroPhoria plugs gap with live micro herbs and micro greens offer for chefs [online] Available at: http://www.producebusinessuk.com/supply/stories/2015/07/22/hydrophoria-plugs-gap-with-live-micro-herbs-and-greens-offer-for-chefs [Accessed 11 May 2019].

- Microfarms, 2017. Microfarms Monterrey [online] Available at: https://www.facebook.com/MicrofarmsMty/ [Accessed 11 May 2019].

- MicroVeggy, 2019. MicroVeggy. [online] Available at: https://www.microveggy.com/selling-microgreens/

- Treadwell, D. D., Hochmuth, R., Landrum, L., & Laughlin, W., 2010. Microgreens; A New Specialty Crop. [online] Available at: http://eco-library.theplanetfixer.org/docs/microgreens/microgreens-a-new-specialty-crop.pdf [Accessed 11 May 2019].

- Playerbas, 2017. Playerbas [online] Available at: https://www.playerbas.com/ [Accessed 11 May 2019].

- Xiao, Z., 2013. Nutrition, Sensory, Quality and Safety Evaluation of A New Specialty Produce: Microgreens. [online] Available at: http://drum.lib.umd.edu/bitstream/handle/1903/14900/Xiao_umd_0117E_14806.pdf?sequence=1&isAllowed=y [Accessed 11 May 2019].

Article Rights and License

© 2019 The Authors. Published by Sprint Investify. ISSN 2359-7712. This article is licensed under a Creative Commons Attribution 4.0 International License.