KeywordsClothing Fast fashion Quick response Retail Retailing South Africa Supply Chain

JEL Classification M31

Full Article

1. Introduction

The clothing industry has been described as complex due to its strong competition and the short life cycle of products (Liu et al., 2013). Retailers have to constantly assess their business models and strategies to ensure that they remain competitive. In the apparel sector, fast fashion (FF) is a well-recognised strategy (Su and Chang, 2018) that aims to reduce processes in the buying cycle (Barnes and Lea-Greenwood, 2006). The main objective of FF is to meet the consumer demand for current fashion trends as quickly as possible and at low prices (Cook and Yurchisin, 2017). Another definition describes FF as a positioning strategy that allows for a quick response to the latest fashion trends by continually providing new products (Byun and Sternquist, 2008). This strategy has developed because of the increasing globalisation and digitisation in the world economy (Backs et al., 2020).

The rapidly changing fashion habits of consumers puts pressure on retailers to be able to meet these rapidly changing consumer needs (Camargo et al., 2020). For this an effective supply chain (SC), which is a key factor in retailing (Barnes and Lea-Greenwood, 2006), with a sound relationship between retailers and suppliers becomes critical. The FF strategy requires an effective and responsive SC, so retailers and manufacturers in the USA developed the Quick Response (QR) concept to stay competitive with offshore markets (Birtwistle et al., 2003).

The South African (SA) apparel retail industry has long standing, well known retailers who have been in the market for years. Woolworths, the TGF group, Truworths and Edgars all form part of the high-end market, while Mr Price, Legit, Jet, Ackermans and Pepkor form the value chain segment. The SA clothing industry, both retailers and manufacturers, have endured difficult times with open markets and globalisation, which resulted in government interventions on high end imports with the implementation of quotas and tariffs. Retailers have had to rethink their SC strategies and the shift in sourcing which affects deliveries, quality & prices (Lambrechts, 2009). Fast fashion has thus become an important strategy for SA clothing companies and some SA retailers have even opened offices in Shanghai, (for example, retail chains Pepkor and Edcon) to be closer to their manufacturers (Lambrechts 2009).

Although considerable research has been done internationally on the critical factors for FF success, very little has been done in South Africa (White, 2017). Therefore, the purpose of this research study is to identify the various factors that comprise the QR and SC activities in the FF clothing industry in a developing country, namely South Africa, and then to investigate the relative importance of these factors via a case study of one of the main FF retailers in SA. Thus, this study contributes new knowledge about the use of a FF strategy in a developing country such as SA.

The paper will first present extant literature relevant to QR and SC in FF. Then the methodology used for the study will be explained, after which the findings from the empirical research will be presented. Finally, the findings will be discussed and recommendations for the SA FF clothing industry will be made, as will suggestions for further research.

2. Literature Review

“Supply chain agility and supply chain collaboration” are, according to Moon and Lee (2017, p. 293), significant strategic tools in environments such as inhabited by FF. These two concepts have been operationalised in this study as QR and SC from the lens of the resource-based view, which Gómez and Koroscik (2016) suggest is the most appropriate theory for studying and contextualising FF (Seo and Kim, 2015). Fawcett et al. (2010) stress that a single company can rarely possess all the resources need for competitive advantage and so they stress the importance of adopting a relational view, which looks upon collaborations between firms as means to increase capabilities, knowledge and competitive advantage (Shih and Agrafiotis, 2017). Thus, this literature review is conducted from the resource-based and relational views.

2.1 Quick Response (QR)

Quick response is a method that allows local manufacturers to respond or compete with low offshore prices through collaboration between retailers and manufacturers (Birtwistle et al., 2003;), especially in situations where customer behaviour is unpredictable (Fares et al., 2018. Geographic proximity is important in the QR method. However, one of the greatest arguments is that QR is market driven (Fernie and Grant, 2015). Although QR is initially said to be more successful with basic products, it has now proven to be even better with fashion products (Lipol, 2015).

Strong competition and volatile demand require companies to react quicker to customers’ needs by shortening both product life cycles and delivery times through increased flexibility and responsiveness (Moon et al., 2017; Golobovante et al., 2018). This need for responsive supply chains results in new methods. Kurt Salmon Associates (KSA), in the United States of America (USA), developed a Quick Response (QR) method by studying the apparel industry in 1986 to create a tool to improve response time and compete against offshore markets (Birtwistle et al., 2003; Jeacle, 2015). In this study, KSA found that it took an average of sixty-six weeks for clothing to move from manufacturer to retailer, despite a production time of eleven weeks (Aftab et al., 2017). Quick Response’s main factor is time, which includes all company activities in the SC being extremely efficient. QR is only possible through a partnership or collaborative strategy where supplier and retailer look for ways to respond quickly to consumer demand (Hodson, 2019), making management of inventory more agile (Golobovante et al., 2018).

Fast fashion retailers rely heavily on QR to be able to offer fashion forward/trending clothing and short life cycle products with enhanced design (Cachon and Swinney, 2011). FF is a strategy that promotes QR through the optimization of product value and demand for short life cycle products. The retailers utilize fashion trends, which is done quickly and effectively through enhanced designs and product assortment (Choi et al., 2011). The FF strategy has given retailers the ability to respond to current trends by ensuring that stores constantly offer fresh new styles that appeal to customers. This can be as much as daily or weekly (Payne, 2016). Fast Fashion makes use of the principals drawn from the QR method allowing for retailers to effectively respond to market demand (White, 2017). This business strategy has thereby put pressure on the rest of the industry to produce more at a lower cost (Hellström, 2017).

For retailers to achieve a balanced supply and demand strategy, joint efforts with all stakeholders in the industry is key (Castelli and Brun, 2010). The need for the speed to market approach is crucial in today’s business and this time-based method allows for shorter cycles. This is also achieved through good information systems that integrate internal and external information (Golobovante et al., 2018).

Improving the efficiency of QR collaboration and vertical integration is of great importance (Bruce et al., 2004). A QR system requires an old-fashioned supplier/buyer relationship, in which the buyer and supplier work closely together through information sharing. This also becomes a survival strategy for the domestic market against cheap imports (Fernie and Azuma, 2004). An important factor that influences effectiveness is information, achieved through sales and customer feedback. QR helps to reduce inventory levels, improving the possibility of less items having to go on sale at the end of season (Cachon and Swinney, 2011). The use of QR improves the ability to make information driven decisions (Christopher and Towill, 2002).

Benefits of QR include shorter product development cycles, maximum sales volumes, reduced product development expenses, reduced stock holdings, increased stock turnovers and improved customer service due to a competitive edge. In addition, the number of markdowns is reduced, and flexibility is improved. QR is said to have improved sales by 40% where it has been implemented in yarn, fabric and garment manufacturers and distributors (Bruce and Daly, 2011; Cachon and Swinney, 2011). The QR model pilot was first done in SA with two retailers and local manufacturers in 2013, with a total of 159 orders being on the QR programme. They achieved a lead time of 56 days with products being adjusted in response to point of sale information. TFG has subsequently further reduced their average lead time to 42 days by using a local SC, whereas international SCs average between 150 to 180 days (Theunissen, 2020). In addition, the products were sold at full price, which provided retailers with higher retained margins (Morris and Barnes, 2014).

2.2. Supply Chain

2.2.1. Factors of Importance in the Supply Chain

The SC in the fashion industry includes the entire gamut of processes, ranging from acquisition of raw materials right through to the finished product arriving at the marketplace (Camargo et al., 2020). Coordination of supply chains is of vital importance, with retailers always looking for new ways to update their supply chains (Moon et al., 2018). Supply chains have become highly complex with increasing globalisation. Due to the length and complexity of SCs in the apparel industry, new strategies have been put in place in order to negate long buying cycles and respond to the demands of customers (Backs et al., 2020: Camargo et al., 2020)

Supply chains constantly evolve, with change being dependent on economic or industry transformation, technology developments, political factors and management decisions (MacCarthy et al., 2016). The importance of differentiation and development of sustainable competitive advantage is crucial in retailing (Cagliano et al., 2011). In modern retail it is the SC that competes rather than the companies (Perry and Wood, 2018).

Strategic partnerships are imperative in the SC (Barnes and Lea-Greenwood, 2006), as are good relationships, both internal and external, with interdependence among SC members (Moon et al., 2018). A number of strategies have been developed in the clothing SC, including Just-in-Time (JIT), QR, and Lean and Agile SCs. Although overseas sourcing may also create a low-cost advantage, there is a potential risk of this not occurring due to changes in exchange rates (Bhardwaj and Fairhurst, 2010). Rapid changes in fashion markets demand flexibility and responsiveness from retailers and how well this is handled will result in success or failure of the business (Chan et al., 2017).

2.2.2. Supply Chains in the Clothing Industry

In the clothing industry the same principals and fundamentals of SCs apply. However, what are of great significance are the lessons from the FF business model on flexibility and responsiveness to current trends which create the need for reduced cycle times (Backs et al., 2020; Camargo et al., 2020).

Clothing retailers have mostly sourced mass production in low wage countries such as China in search of resources and low prices. The nineties saw significant changes in geographic sourcing from manufacturing in low-cost countries to sourcing across the world (Guercini and Runfola, 2004). The traditional clothing cycle was long and lacked flexibility. With changes in demand, the need for a speedy and flexible SC became of crucial importance to retailers. A faster SC minimised the impacts of inaccurate forecasting and assisted in responding to demand by making use of faster and geographically closer SCs (Guercini and Runfola, 2004). Collaboration within an agile SC has been found to be critical to success in FF (Moon et al., 2018)

2.2.3. Agile Supply Chain

The concept of agile SC describes short lead times, flexibility and demand driven concepts (Barnes and Lea-Greenwood, 2006). This is what is needed for retailers to keep up in these volatile markets. Agility is the ability to move easily and quickly which requires businesses to embrace organisational structures, information systems, logistics and mind-sets (Yu et al., 2012; Chan et al., 2017). The concept of agility was introduced to be ahead of all the best practices at that time. During this time companies were forced to search beyond cost and quality advantage to cope with market volatility (Zheng, 2010).

It is never easy to predict the rapid and highly fickle trends of fashion with high competition. An agile SC is said to play a central role with all the resources sharing in the improvement of speed to market (Cerruti et al., 2016). The agile SC has minimal lead times and the ability to service volatile consumer demand (Bruce and Daly, 2011). According to Guercini and Runfola (2004), this type of SC is driven by low quantities and exclusivity, which is what companies such as Zara have been trying to perfect. The integration of the SC increases performance (Wong et al., 2011), whilst the key characteristic of an agile business is flexibility (Brusset, 2016; Chan et al., 2017). This is what FF needs to keep up with evolving trends. The use of an agile SC has been identified in previous research on both Zara and H & M for their high fashion products (Caro and Martìnez-de-Albèniz, 2014).

2.2.4. Lean Supply Chain

Another concept seen in FF supply chains is the lean SC which focuses on the elimination of waste, including time. The lean SC is a multi-dimensional approach that embraces a range of management practices including equipment management, cellular manufacturing and quality control (Banihashemi, 2011). This method talks to reduced throughput time. The primary goal of lean is the creation of the right products demanded by consumers at the time they want them (Bowersox et al., 2013). Lean relies on rapid replenishment, strict requirements of delivery times and the completion of accurate orders (Asif et al., 2019). In this chain, demand is predictable, there is less assortment and long product life cycle (Banihashemi, 2011). Most retailers use this method for manufacturing their core products, enjoying low costs (Asif et al., 2019). There are long term contracts which include price as a factor (Guercini and Runfola, 2004). Thus, lean is not suitable for the unpredictability and volatility of FF.

2.2.5. Leagile Supply Chain

Leagile supply chains are a combination of both lean and agile for ideal SCM (Bruce and Daly, 2011). Suppliers can use both lean and agile methods depending on product types. H & M is an example of a business currently doing this (Caro and Martìnez-de-Albèniz, 2014). The retailer must consider using agility for vertical integration and become lean upstream. This can have cost effective results in the upstream chain and promote high service levels downstream (Asif et al., 2019).

Towill and Christopher (2002) explain that leagile can be used where demand can be predicted, whilst the agile method can be applied to new products where demand is volatile. Roll (2010) discusses the taxonomy with respect to SC relationships strategy, flexibility and performance. This taxonomy guides the selection of an appropriate global SC. Key dimensions are highlighted with respect to replenishment lead times and predictability or variability of demand. There is continuous replenishment where demand is predictable and postponement when demand is unpredictable, with lengthy lead times. In a situation where demand is unpredictable, but lead times are short, an agile method would be required.

According to Van Zyl and Matswalela (2016) agile concepts are similar to those of lean, including flexible setup, time minimization, cross-trained employees, supplier relationship, quality assurance, short lead time and reduced costs. This shows that agile and lean are complimentary. These similarities measure the same on the use of market knowledge and lead time compression. However, they differ in robustness and smooth demand (Zheng, 2010). Some authors argue that the two concepts cannot co-exist, since lean requires simplification and standardisation whilst agility promotes flexibility thus the claim that these cannot work hand in hand (Zheng, 2010; Ciarniene and Vienažindiene, 2014).

2.2.6. Conclusion

The implementation of agile SC’s in FF reduced lead times from 66 weeks to about 3-5 weeks for FF retailers such as Zara, H & M and Forever 21 (Bhardwaj and Fairhurst, 2010; Lipol, 2015). The literature indicates that agility is crucial in FF. The SC methods play a vital role when retailers want to be competitive in this fickle industry characterised by short life cycles, high volatility and low predictability (Cerruti et al., 2016). It is therefore important to have flexible manufacturing methods. However, in instances of staple or basic product the concept of lean supply, which can be planned and is more manageable, can be used due to its predictability, with longer lead times for items that have a longer life cycle and are higher in volume (Linden, 2016). It is important to note that the SA clothing SC may be restricted in competitiveness due to lack of raw material supply locally and to skills shortages.

3. Method

3.1. Research Design

This research followed a positivistic paradigm, using a quantitative survey based on a questionnaire with closed ended responses that were analysed statistically. The study used a case method, being conducted in one of the major clothing retailers in SA. They have been named Alpha Clothing to maintain their anonymity which they required as a condition of participation.

3.2. Population and Sampling

The target population for this study was made up of managers and employees in the following departments: Buying, Planning, Resource, Trend & design, SC, Ethical, Operations and Quality. These departments were selected as they are the key stakeholders in the clothing retail chain and due to a comprehensive induction scheme and staff rotation, these staff all have a sound understanding of the various roles each department plays in the SC. The number of employees in these departments comprising the population was 225.

For this study, non-probability purposive sampling techniques were employed to firstly select the company to be used as a case study. Alpha was selected as it is a major FF retailer and the researchers had personal contact in the company, which enabled access. The second step was to select the key departments within Alpha to be included, again via purposive sampling. As mentioned, these were the key departments involved in the SC. Step three used convenience sampling to select respondents to complete the questionnaire. Since participation was voluntary the sample was self-selected. With a 95% level of significance, an allowed error of 0,1 (on a 5-point Likert type scale) and assuming a variance of 1, the t-distribution requires a sample size of 144 for a population of 225 (excluding a correction factor) (Sekaran & Bougie, 2013).

The relevant departments and their employees, comprising the population, and the responses achieved, which comprises the sample, are illustrated in Table 1.

Table 1. Population and sample

| Target Population | Sample Achieved | |||

| Department | Employees | % of population | Responses | % of sample |

| Planning | 87 | 38.7 | 34 | 34.0 |

| Buying | 64 | 28.4 | 26 | 26.0 |

| Operations | 29 | 12.9 | 2 | 2.0 |

| Quality | 22 | 9.8 | 21 | 21.0 |

| Trend & Design | 11 | 4.9 | 7 | 7.0 |

| Resource | 5 | 2.2 | 2 | 2.0 |

| Supply Chain | 4 | 1.8 | 4 | 4.0 |

| Ethical | 3 | 1.3 | 3 | 3.0 |

| Other | 1 | 1.0 | ||

| TOTAL | 225 | 100 | 100 | 100.0 |

Despite numerous follow ups, including email reminders and personal reminders, the required sample could not be achieved in this study. However, the achieved sample is still above Sekaran and Bougie's (2013) suggestion of a minimum acceptable sample of 30. Furthermore, at least two responses were obtained from each department, thus representing a spread across all departments. Therefore, this sample was accepted as adequate for analysis, but it is also accepted that a small convenience sample is a limitation of this study, and any findings should not be seen as more than exploratory.

3.3. Data Collection

The research was conducted as a case study in one of the major South African clothing retailers. Data was collected by means of a questionnaire structured with closed ended questions.

3.3.1. Data Collection Instrument

The questions were derived from the existing literature, as illustrated in Table 2.

Table 2. Source and derivation of questionnaire

|

The questionnaire made use of a 5-point, Likert-type scale, anchored with 1 = Strongly Disagree and 5 = Strongly Agree. The questions were pilot tested by two subject matter experts and a statistician. As a result of this pilot study, only one question needed to be modified and refined after receiving the feedback so as to ensure the understanding of the respondents. Then ten industry/subject matter experts were selected to participate in a pre-test of the questionnaire. These comprised clothinglecturers, industry analysts, retail managers, researchers, and SC managers/staff from other, but similar clothing retailers. The pre-test was done in the form of an online questionnaire with a link sent via email. The pilot study and the pre-test together showed face and content validity to be acceptable. i.e., the constructs being researched are explained by the questions in the questionnaire, which is to be expected since the questions came from previously validated questionnaires in the literature. As illustrated in Table 4, the Cronbach’s Coefficient Alpha showed adequate reliability, given there are so few items in each scale. Thus, no further changes needed to be made to the final questionnaire.

3.3.2. Administration of the Instrument

The questionnaire, structured with a link embedded in an e-mail, was sent to all managers and employees in the eight departments via electronic mail and WhatsApp. Saied et al. (2014) state that most individuals check mail on their cellular phones more often than on their computers. For this reason, it was decided to send the questionnaire survey via WhatsApp, as well as by email. Responses were tracked daily and follow up emails were sent as reminders to the recipients. Personal contact was also made to encourage responses, which culminated in a response rate of 45%. Since Diamantoupoulis and Schlegelmilch (1997) suggest that a sample of 100 for a major breakdown is adequate, we accepted the 101 useable questionnaires for analysis.

3.4. Data Analysis

Data was captured via Excel and then analysed using the Statistical Package for Social Sciences (SPSS) version 25. It was processed and thoroughly checked for administrative errors. The results are presented as descriptive statistics (means of variables and questions) and as graphs and tables using summarised percentages for each of the departments, and for each of the Likert response categories, to show the level of agreement or disagreement with the statements that constitute each variable. Furthermore, an Analysis of Variance (ANOVA) was conducted to identify any differences in perceptions between the different departments. This provides respondents’ scoring patterns per variable per department. In order to test for significant agreement or disagreement, a one-sample t-test was applied to test the average agreement score against the scalar value of '3' (the central score of the Likert scale).

3.5. Ethical Issues

Ethics clearance was granted by the DUT ethics committee for this research - FREC No: 224/16FREC. Written permission was obtained from Alpha’s management, Human Resources department and legal team. A covering letter that informed the respondents on the objective of the study as well as their right to withdraw from participating in the study and that their data would be treated with confidentiality and responses would be anonymous.

4. Findings

4.1. Sample Profile

Table 1 reflects the structure of the sample, showing that the Planning department provided the highest proportion at 34% and the smallest departments being Operations and Resource at 2% each. Since the respondents are spread across all departments, and there were at least two responses from each department, it was concluded that the sample is adequate to represent the opinions of the population.

4.2. Descriptive Statistics

Before dealing with the composite measures (constructs), univariate analysis was conducted on the items included in these composite measures. Analysis using a one-sample t-test was done to determine if there is significant agreement or disagreement with each statement in the questionnaire.

The results are summarised in Table 3, which illustrates the constructs and their related questions, together with their response frequencies, and the results of the t-test.

Table 3. Univariate statistics and test of significance

| Construct | Variables | Item | Responses as Frequency (%) | n | Mean (SD) | t | df | p-value | ||||

| Strongly disagree | Disagree | Neutral | Agree | Strongly agree | ||||||||

| Strategy | QR encourages the use of local suppliers | - | 1 (1) | 9 (8.7) | 42 (40.4) | 52 (50) | 104 | 4.39 (0.689) | 20.649 | 103 | <.0005* | |

| Quick response (QR) | QR will have a positive impact on the purchase of goods from local suppliers | - | 2 (1.9) | 10 (9.6) | 46 (44.2) | 44 (42.3) | 102 | 4.29 (0.726) | 18.013 | 101 | <.0005* | |

| Time saving | QR helps to reduce buying mistakes | 1 (1) | 21 (20.2) | 30 (28.8) | 32 (30.8) | 20 (19.2) | 104 | 3.47 (1.052) | 4.569 | 103 | <.0005* | |

| QR reduces the amount of time spent on season planning | 1 (1) | 28 (26.9) | 19 (18.3) | 42 (40.4) | 10 (9.6) | 100 | 3.32 (1.024) | 3.126 | 99 | .002* | ||

| QR helps to achieve frequent deliveries to stores | - | 9 (8.7) | 10 (9.6) | 58 (55.8) | 26 (25) | 103 | 3.98 (0.84) | 11.848 | 102 | <.0005* | ||

| Flexibility | The supplier is willing to change the variety of goods at any given time because of QR | - | 9 (8.7) | 31 (29.8) | 45 (43.3) | 17 (16.3) | 102 | 3.69 (0.856) | 8.099 | 101 | <.0005* | |

| QR creates the ability to respond quickly to shifts in demand | - | 2 (1.9) | 3 (2.9) | 45 (43.3) | 53 (51) | 103 | 4.45 (0.653) | 22.493 | 102 | <.0005* | ||

| QR creates the ability to increase operational capacity | - | 6 (5.8) | 22 (21.2) | 58 (55.8) | 16 (15.4) | 102 | 3.82 (0.763) | 10.898 | 101 | <.0005* | ||

| QR gives the ability to change planned delivery dates to meet emergent requirements | - | 5 (4.8) | 21 (20.2) | 58 (55.8) | 18 (17.3) | 102 | 3.87 (0.753) | 11.695 | 101 | <.0005* | ||

| Supply chain (SC) | Strategy | SC enables more frequent product innovation | - | 10 (9.6) | 13 (12.5) | 45 (43.3) | 21 (20.2) | 89 | 3.87 (0.907) | 9.000 | 88 | <.0005* |

| SC allows the buyer to pick up on trends faster and more accurately | - | 9 (8.7) | 26 (25) | 42 (40.4) | 12 (11.5) | 89 | 3.64 (0.843) | 7.170 | 88 | <.0005* | ||

| SC enables leverage in existing competencies | 1 (1) | 3 (2.9) | 21 (20.2) | 54 (51.9) | 10 (9.6) | 89 | 3.78 (0.735) | 9.955 | 88 | <.0005* | ||

| SC enables the introduction of more new styles per year | 3 (2.9) | 16 (15.4) | 20 (19.2) | 38 (36.5) | 12 (11.5) | 89 | 3.45 (1.045) | 4.059 | 88 | <.0005* | ||

| SC allows more accurate timing in introducing new products to the market | 1 (1) | 4 (3.8) | 25 (24) | 43 (41.3) | 15 (14.4) | 88 | 3.76 (0.83) | 8.601 | 87 | <.0005* | ||

| SC supports implementation of low cost production plans | 1 (1) | 10 (9.6) | 25 (24) | 45 (43.3) | 8 (7.7) | 89 | 3.55 (0.853) | 6.089 | 88 | <.0005* | ||

| * indicates significant at the 95% level | ||||||||||||

4.3. Perceptions about QR and the SC

This section aims to analyse the important factors for retailers to consider when implementing the FF strategy. This includes an analysis of QR and SC. The analysis will look at the respondent’s level of agreement or disagreement to the questions.

4.3.1. The Importance of QR

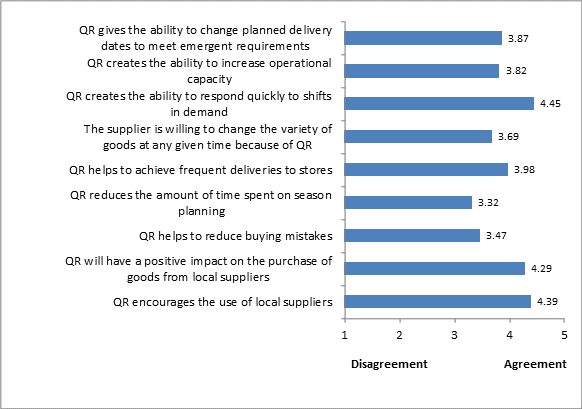

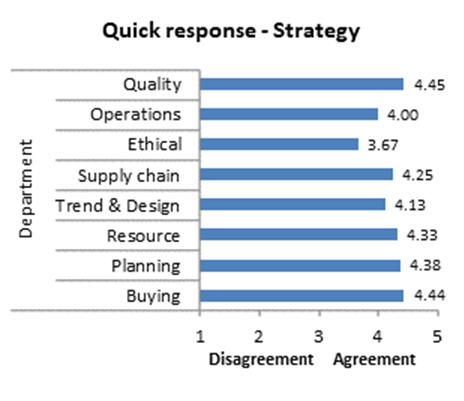

Fast fashion retailers such as ZARA rely on QR in order to be able to offer consumers trendy products with enhanced designs in a short period of time and at a lower cost (Cachon and Swinney, 2011; Hellström, 2017). Thus the key to successful retailing is through the acceleration of product offerings to the mass market (Barnes and Lea-Greenwood, 2006). Figure 1 indicates the average agreement patterns of respondents with regards to QR in Alpha.

Figure 1: The perceived importance of QR in FF strategy at Alpha

The analysis (Table3 and Figure 1) shows that there was significant agreement to all the statements. This indicates that QR is perceived as an important strategy in implementing FF. The most important use for implementing fast fashion is that QR creates the ability to respond quickly to shifts in demand. From a South African viewpoint, QR is perceived as being important in encouraging the use of local suppliers and having a positive impact on purchasing from local suppliers. Thus, the QR aspect of FF can be seen as important for the development and sustainability of the South African clothing and fashion industry.

The least important (although still significantly important) statements were ‘QR reduces the amount of time spent on season planning’ and ‘QR reduces buying mistakes’. Comparing this finding to the most important aspects of QR mentioned previously, it can be seen that QR is perceived as more important from an external, strategic and effectiveness viewpoint, rather than an internal efficiency viewpoint.

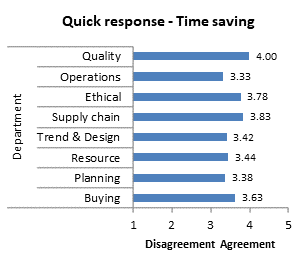

4.3.2. The Importance of the SC

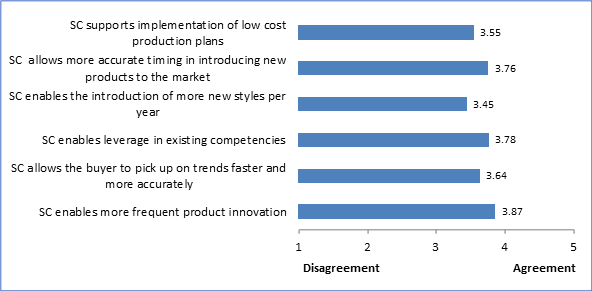

Figure 2 indicates the average agreement patterns of respondents with regard to the importance of SC in Alpha.

Figure 2: The importance of the SC in FF

As for the QR items, there was significant agreement to all these SC items. The greatest perceived importance was ‘SC enables more frequent product innovation’ and the least perceived importance was ‘SC enables the introduction of more new styles per year’. However, unlike QR, none of the statements scored above 4 on the Likert scale, thus indicating that QR was generally perceived as more important than SC. Despite this perceived ‘lesser importance’, it must still be noted that the perceptions were above the midpoint of ‘3’ and were statistically significant, indicating that SC is important in the implementation of FF.

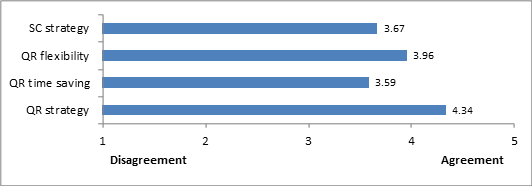

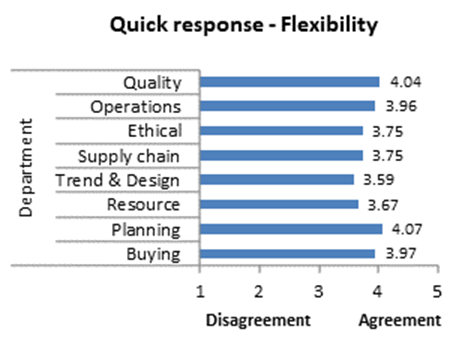

4.3.3 Construct Analysis

Having assessed the individual statements (univariate analysis), the individual items are combined to form four constructs, as highlighted in the literature, by averaging agreement scores across the items in a construct. These constructs were named QR strategy, QR time saving, QR flexibility and SC strategy, and were found to be reliable, given the small number of items in each scale, as per the Cronbach coefficient alpha scores as shown in Table 4 (Ursachi et al., 2015.

Table 4: QR and SC variable statistics

| Construct | Sub-construct | n | Mean (SD) | t | df | p-value | Cronbach α |

| Quick response | Strategy | 104 | 4.34 (.600) | 22.782 | 103 | <.0005* | 0.622 |

| Time saving | 104 | 3.59 (.736) | 8.147 | 103 | <.0005* | 0.630 | |

| Flexibility | 104 | 3.96 (.522) | 18.807 | 103 | <.0005* | 0.611 | |

| Supply chain | Strategy | 89 | 3.67 (.630) | 10.101 | 88 | <.0005* | 0.815 |

* indicates significant at the 95% level

Analysis showed that there was significant agreement that each of these constructs is important when making use of an FF strategy. Analysis from a repeated measures ANOVA showed that there is a significant difference in perceived importance of these four variables when implementing a FF strategy (F (3, 264) = 45.284, p<.0005). QR strategy is perceived as significantly more important than the other three variables, with QR flexibility being perceived as significantly more important than QR time saving and SC strategy. This finding is illustrated in Figure 3.

Figure 3: Mean scores for composite variables

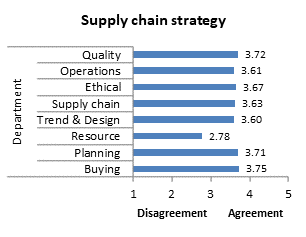

4.3.4 Perceptions per Department

Analysis to determine if there were significant differences in these four constructs across departments revealed no significant differences. Any apparent differences apply only to the specific sample and not to the population, and so will not be discussed further.

|

|

|

|

Figure 4: The importance of QR and SC as FF strategies as perceived per department

5. Discussion

Multiple studies have identified the importance of QR in the international clothing retail industry, for example, Cortez et al. (2014); Taplin (2014a); Jeacle (2015); Payne (2016) and Nuševa and Maric (2017). QR has also been widely researched in the SA clothing industry, but such research had been mainly focused on manufacturing until White (2017) examined the impact of QR in the SA retail sector. Regarding SC, previous research has indicated the importance of an effective SC (Bruce and Daly, 2011; Hodson, 2019). Zara’s SC is one of the most widely researched SCs in the clothing retail business (both academically and in the business sector) due to their great success over the years (Ahmad, 2012; Taplin, 2014; Uriarte Elizaga, 2016; Aftab et al., 2018). However, most of this research has been conducted internationally, with only the research conducted by Moeng (2011) focusing on the consumer perspective of FF in SA.

The objective of this study was to identify issues of importance when implementing FF. The two major factors critical to implementation of FF as identified through the extant literature, namely QR (e.g., Golobovante et al., 2018; White, 2017; Lipol, 2015; Cachon and Swinney, 2011) and the SC (e.g., Backs et al., 2020; Camargo et al., 2020;Moonet al., 2018; Guercini and Runfola, 2004), have also been confirmed via this study’s analysis to be important for successful implementation of FF in South Africa. Fast fashion aims to reduce the process involved in the buying cycle and to reduce the lead times of getting fashionable products in store to satisfy consumer demand (Barnes and Lea-Greenwood, 2006; Jeacle, 2015). The need for retailers to remain competitive in this market is crucial, therefore the need for retailers to ensure they have an effective SC. Through the implementation of QR in the SC, retailers can reduce buying mistakes, as indicated in the question ‘QR helps reduce buying mistakes’, and pick up on trends faster and more accurately, as the question ‘the SC allows the buyer to pick up on trends faster and more accurately’ indicates.

The fashion business is one that depends on a well-defined SC, therefore the crucial need to recognise concepts such as QR (Barnes and Lea-Greenwood, 2006). The reduced cycle time in FF forces or encourages retailers to source locally, with 94.8% of this study’s respondents strongly agreeing with this. This highlights one of the benefits of FF, namely the revival of local production. This supports Steyn (2014), who indicates that most SA retailers agree that local manufacturing enables a quick response to the market and to developing trends. This finding is further support for the importance of local production to FF, as illustrated by The Foschini Group (TFG) that has factories which are able to achieve a lead time of 32 days (Moeng, 2011). Although this is slow in comparison to Zara’s 2-week lead time, it is still an achievement in the SA clothing industry. This is a step in the right direction for a retailer who has invested in implementation of the FF strategy because one of the key drivers of FF implementation is rapid response (Miller, 2013; Payne, 2016), as supported by the time saving variable shown in this study to be of significant importance to FF implementation. TFG’s improved annual results were credited to the businesses’ ability to adopt three specific factors of FF namely: shorter lead times, improved customer positioning and change in supplier selection criteria (Moeng, 2011). The results from this study thus support these findings from the literature.

From the above analysis and discussion, it can be seen that the research question “What are the implications to implementing the FF strategy” has been answered. The study findings have confirmed the importance of both QR and SC to a successful FF implementation in a developing country like SA.

6. Implications

6.1. Managerial Implications for Retailers

Limited studies have been conducted in SA on the FF strategy and so this study bridges the gap between knowledge of FF strategies and SC, and retail operations. Trade and consumption have no borders, as consumers are able to shop anywhere in the world from the comfort of their homes. Therefore, the importance of keeping up to date with business strategies that promote company success cannot be over emphasised. It is therefore advised that SA retailers incorporate the principals identified in this study into their company strategies. Of especially importance is to build strong and trusting collaborations and partnerships with their suppliers and other SC members to improve information and to speed up production throughput, product development, inventory replenishment and distribution, and in the process to reduce costs.

The SC is a crucial part of the business, with an effective and agile SC being identified as one of the key factors of success in modern retail. Retailers need to recognize the importance of an effective and efficient SC and should emphasise using domestic suppliers to improve their agility and flexibility.

6.2. Theoretical Contribution for Academics

This research has added to the body of knowledge about FF strategy in the SA clothing retail industry, especially from resource-based and relational views, which have not been clarified in the little past research that has been done in SA. This is one of the first studies to research the FF strategy in SA, thus laying the foundation for further academic research that will allow greater understanding of clothing retail strategies from a resource-based and relational perspective.

7. Limitations and Future Research

7.1. Limitations of Study

There are a number of limitations relevant to this research that were identified during this study. The following were taken into consideration:

- The study was not conducted across all clothing retailers of South Africa; since it was a case study of one retailer the results should be generalised with care.

- A sample size of one hundred respondents with only 2 respondents in two departments mean the results must be interpreted with care.

- Since the questionnaire was self-completion, the sample was essentially self-selected and so might not be representative of the population, i.e., non-respondents may differ in significant ways to respondents.

Despite these limitations, the findings are still worth considering from an exploratory point of view. Since this was the first research of its type in SA, it will contribute to knowledge about fast fashion in SA and hopefully will initiate a continuing stream of research into FF.

7.2. Future Directions of Research

The following are suggested for further research:

- This study focused on only one SA retailer. A broader study should be conducted, including more SA retailers

- The study was conducted only on key factors influencing the implementation of FF. Research into the specific drivers and barriers to the implementation of FF in the SA retail market is needed

- A qualitative study to investigate deeper into the extent participants really understand the FF concept would be worthwhile.

References

- Aftab, M., Yuanjian, Q. and Kabir, N., 2017. Postponement application in the fast fashion supply chain: a review. International Journal of Business and Management, 12 (7), pp. 115-128.

- Ahmad, H., 2012. Responsiveness and Collaboration in the Fashion Supply Chain. Unpublished M.Phil. dissertation, University of Manchester.

- Alamgir, F. and Banerjee, S.B., 2019. Contested compliance regimes in global production networks: Insights from the Bangladesh garment industry. Human Relations, 72 (2), pp. 272-297.

- Backs, S., Jahnke, H., Lüpke, L., Stücken, M. and Stummer, C., 2020. Traditional versus fast fashion supply chains in the apparel industry: an agent-based simulation approach. Annals of Operations Research. https://doi.org/10.1007/s10479-020-03703-8.

- Banihashemi, S.A., 2011. Improving supply chain performance: The strategic integration of lean and agile supply chain. African Journal of Business Management, 5(17), pp. 7557-7563.

- Barnes, L. and Lea-Greenwood, G., 2006. Fast fashioning the supply chain: shaping the research agenda. Journal of Fast Fashion Marketing and Management. 10(3), pp. 259-271

- Bhardwaj, V. and Fairhurst, A., 2010. Fast fashion: response to changes in the fashion industry. The International Review of Retail, Distribution and Consumer Research, 20(1), pp. 165-173.

- Birtwistle, G., Fiorito, S.S. and Moore, C.M., 2006. Supplier perceptions of quick response systems. Journal of Enterprise Information Management, 19(3), pp. 334-345.

- Birtwistle, G., Siddiqui, N. and Fiorito, S.S., 2003. Quick response: perceptions of UK fashion retailers. International Journal of Retail & Distribution Management, 31(2), pp. 118-128.

- Bowersox, D.J., Closs, D.J., Cooper, M.B. and Bowersox, J.C., 2013. Supply chain logistics management. 4th ed. New York: McGraw-Hill.

- Bruce, M. and Daly, L., 2006. Buyer behaviour of fast fashion. Journal of Fashion Marketing and Management, 10(3), pp. 329-344.

- Bruce, M. and Daly, L., 2011. Adding value: challenges for UK apparel supply chain management – a review. Production Planning & Control, 22 (3), pp. 210-220.

- Bruce, M., Daly, L. and Towers, N., 2004. Lean or agile. A solution for supply chain management in the textiles and clothing industry?. International Journal of Operations and Management, 24(2), pp. 151-170.

- Brusset, X., 2016. Does supply chain visibility enhance agility?. International Journal of Production Economics, 171, pp. 46-59.

- Byun, S.E. and Sternquist, B., 2008. The antecedents of in-store hoarding: Measurement and application in the fast fashion retail environment. International Review of Retail Distribution & Consumer Research, 18, pp. 133-147.

- Cachon, G.P. and Swinney, R., 2011. The value of fast fashion: Quick response, enhanced design, and strategic consumer behavior. Management Science, 57(4), pp. 778-795.

- Cagliano, A.C., DeMarco, A., Rafele, C. and Volpe, S., 2011. Using system dynamics in warehouse management: a fast fashion case-study. Journal of Manufacturing Technology Management, 22(2), pp. 1717-1188.

- Camargo, L.R., Pereira, S.C.F. and Scarpin, M.R.S., 2020. Fast and ultra-fast fashion supply chain management: an exploratory research. International Journal of Retail & Distribution Management, 48(6), pp. 537-553.

- Caro, F. and Martìnez-de-Albèniz, V., 2014. Fast fashion: Business model overview and research opportunities. In: Agrawal, N. and Smith, S. A. eds. Retail supply chain management: Quantitative models and empirical studies. 2nd ed. New York, NY: Springer.

- Castelli, C.M. and Brun, A., 2010. Alignment of retail channels in the fashion supply chain: An empirical study of Italian fashion retailers. International Journal of Retail & Distribution Management, 38(1), pp. 24-44.

- Cerruti, C., Mena, C., Skipworth, H. and Tavoletti, E., 2016. Characterizing agile supply partnerships in the fashion industry. International Journal of Operations and Production Management, 36(8), pp. 923-947.

- Chan, A. T., Ngai, E. W. and Moon, K. K., 2017. The effects of strategic and manufacturing flexibilities and supply chain agility on firm performance in the fashion industry. European Journal of Operational Research, 259(2), pp. 486-499.

- Choi, T.M., Chiu, C.H. and To, K.M.C., 2011. A fast fashion safety-first inventory model. Textile Research Journal, 81(8), pp. 819-826.

- Christopher, M., 2000. The agile supply chain: competing in volatile markets. Industrial Marketing Management, 29(1), pp. 37-44.

- Christopher, M., Lowson, R. and Peck, H., 2004. Creating agile supply chains in the fashion industry. International Journal of Retail and Distribution Management, 32(8), pp. 1-26.

- Christopher, M., Peck, H. and Towill, D., 2006. A taxonomy for selecting global supply chain strategies. The International Journal of Logistics Management, 17(2), pp. 277-287.

- Christopher, M. and Towill, D. R., 2002. Developing market specific supply chain strategies. The International Journal of Logistics Management, 13(1), pp. 1-14.

- Čiarnienė, R. and Vienažindienė, M., 2014. Management of contemporary fashion industry: characteristics and challenges. Procedia-Social and Behavioral Sciences, 156, pp. 63-68.

- Cook, S.C. and Yurchisin, J., 2017. Fast fashion environments: consumer’s heaven or retailer’s nightmare? International Journal of Retail & Distribution Management, 45(2), pp. 143-157.

- Cortez, M.A., Tu, N.T., Van Anh, D., Ng, B.Z. and Vegafria, E., 2014. Fast fashion quadrangle: An analysis. Academy of Marketing Studies Journal, 18(1), pp. 1-18.

- Diamantopoulos, A. and Schlegelmilch, B.B., 1997. Taking the fear out of data analysis. London, UK: The Dryden Press.

- Doyle, S.A., Moore, C.M. and Morgan, L., 2006. Supplier management in fast moving fast fashion retailing. Journal of Fashion Marketing and Management, 10(3), pp. 272-281.

- Fares, N., Lebbar, M. and Sbihi, N., 2018. Quick response in fast fashion retail: An optimization supply chain responsiveness model. 4th International Conference on Optimization and Applications (ICOA), 26-27 April, Mohammedia, Morocco. DOI: 10.1109/ICOA.2018.8370565

- Fawcett, S.E., Waller, M.A. and Fawcett, A.M., 2010. Elaborating a dynamic systems theory to understand collaborative inventory successes and failures. The International Journal of Logistics Management, 21(3), pp. 510-537

- Fernie, J. and Azuma, N., 2004. The changing nature of Japanese fashion: Can quick response improve supply chain efficiency? European Journal of Marketing, 38(7), pp. 790-808.

- Fernie, J. and Grant, D.B., 2015. Fashion logistics. London: Kogan Page.

- Fiorito, S.S., Giunipero, L.C. and Yan, H. 1998. Retail buyers’ perceptions of quick response systems. International Journal of Retail & Distribution Management, 26(6), pp. 237-246.

- Ghemawat, P. and Nueno., 2006. ZARA: Fast Fashion. Harvard Business School. Boston Harvard Publishing. December 21. HBS9-703-497, 1-36.

- Golobovante, A.F.M., Ribeiro, P.C.C. and Gomes, C.F.S., 2018. Adoption of Quick Response and inventory management in fast fashion: two case studies in the state of Minas Gerais. Gestão & Produção, 25(3), pp. 557-567.

- Gómez, S. and KoroÅ›cik, A., 2016. Improvement of Store Operations in the fast fashion industry. Unpublished Master of Science thesis, Stockholm, Sweden. [online] Available at: https://kth.diva-portal.org/smash/get/diva2:948538/FULLTEXT01.pdf [accessed 18 March 2021].

- Guercini, S. and Runfola, A., 2004. Sourcing strategies in clothing retail firms: product complexity versus overseas supply chain. Journal of Consumer Behaviour, 3, pp. 1-15

- Hellström, C., 2017. Why We Shop: A study of political consumption in regard to fast fashion. Unpublished BSS thesis, Uppsala University, Sweden.

- Hines, T., 2004. The emergence of supply chain management as a critical success factor for retail organisations. in Bruce, M., Moore, C. and Birtwistle, G. eds. International Retail Marketing – A Case Study Approach, Oxford: Elsevier pp108-122

- Hodson, J., 2019. The collaborative buyer and supplier relationship (BSR) applied to the product development stage in the contemporary UK fast fashion and rapid fashion market. Unpublished MA dissertation, Manchester Metropolitan University, UK.

- Jeacle, I., 2015. Fast fashion: Calculative technologies and the governance of everyday dress. European Accounting Review, 24(2), pp. 305-328.

- Khurana, K. and Ricchetti, M., 2016. Two decades of sustainable supply chain management in the fashion business, an appraisal. Journal of Fashion Marketing and Management, 20(1), pp. 89-104.

- Kim, H., Choo, H.J., and Yoon, N., 2013. The motivational drivers of fast fashion avoidance. International Journal of Fashion Marketing and Management, 17(2), pp. 243-260.

- Lambrechts, L., 2009. An evaluation of the impact of quotas imposed on clothing and textiles imported from China on the clothing and textile manufacturing industry in South Africa. Unpublished MBA dissertation, University of Stellenbosch, South Africa.

- Linden, A.R., 2016. An Analysis of the Fast Fashion Industry. Senior Projects Fall 2016. 30, Bard College. [online] Available at: https://digitalcommons.bard.edu/senproj_f2016/30 [accessed 18 March 2021].

- Lipol, L.S., 2015. Quick Response in the Textile Industries. International Journal of Scientific and Research Publications, 5(9), pp. 1-6.

- Liu, N., Ren, S., Choi, T., Hui, C. and Ng, S., 2013. Sales Forecasting for Fashion Retailing Service Industry: A Review. Mathematical Problems in Engineering, 2013, pp. 1-9. doi:10.1155/2013/738675

- Lowson, B., King, R. and Hunter, A. 1999. Quick Response: Managing the supply chain to meet consumer demand. Chichester: Wiley.

- MacCarthy, B., Blome, C., Olhager, J., Srai, J. and Zhao, X., 2016. Supply Chain Evolution – Theory, Concepts, Science. International Journal of Operations and Production Management, 36(12), pp. 1696-1718.

- Mihm, B., 2010. Fast fashion in a flat world: Global sourcing strategies. The International Business & Economics Research Journal, 9(6), pp. 55-64.

- Miller, K., 2013. Hedonic customer response to fast fashion and replicas. Journal of Fashion Marketing and Management: An International Journal, 17(2), pp. 160-174.

- Moeng, R., 2011. Fast fashion retail: a consumer perspective. Unpublished MBA dissertation, University of Pretoria, South Africa.

- Moon, K-L.K., Lee, J-Y. and Lai. S-Y.C., 2017. Key drivers of an agile, collaborative fast fashion supply chain: Dongdaemun fashion market. Journal of Fashion Marketing and Management, 21(3), pp. 278-297.

- Morris, M. and Barnes, J., 2014. The challenges to reversing the decline of the apparel sector in South Africa. In: Proceedings of International Conference on Manufacturing-Led Growth for Employment and Equality in South Africa. Johannesburg, May 20-21.

- Nuševa, D. and Marić, R., 2017. Quick response logistics in retailing as an information technology based concept. Strategic Management, 22(4), pp. 32-38.

- Payne, A., 2016. Inspiration sources for Australian fast fashion design: tapping into consumer desire. Journal of Fashion Marketing and Management, 20(2), pp. 191-207.

- Perry, P. and Wood, S., 2018. Exploring the international fashion supply chain and corporate social responsibility. In John Fernie and Leigh Sparks, eds. Logistics and Retail Management. 5th ed. Kogan Page, pp. 97-128

- Roll, S., 2010. An empirical study of the supply chain relationships among strategy, flexibility, and performance. Unpublished Master’s dissertation. Open University of the Netherlands. [online] Available at: https://pdfs.semanticscholar.org/5e22/69723ecfb162ed5c388dac23d77981f61fff.pdf [accessed 22 May 2021].

- Saied, A., Sherry, S.J., Castricone, D.J., Perry, K.M., Katz, S.C. and Somasundar, P., 2014. Age-related trends in utilization of the internet and electronic communication devices for coordination of cancer care in elderly patients. Journal of Geriatric Oncology, 5(2), pp. 185-189.

- Sekaran, U. and Bougie, R., 2013. Research Methods for Business: A skill Building Approach. 6th Ed. Chichester: Wiley.

- Seo, M.J. and Kim, M., 2015. A New Integrated Framework for the Sustainable Performance of Fast Fashion Firms. Paper presented at International Textile and Apparel Association (ITAA) Annual Conference Proceedings. 132. [online] Available at: https://lib.dr.iastate.edu/itaa_proceedings/2015/posters/132 [accessed 16 March 2021].

- Shih, W-Y.C. and Agrafiotis, K., 2017. Competitiveness in a Slow Relational Production Network: The Case of London’s Savile Row Tailors. Clothing and Textiles Research Journal, 35(3), pp. 143-155.

- Steyn, L., 2014. SA cottons on to fast fashion. Mail & Guardian, January 12 [online] Available at: https://mg.co.za/article/2014-01-24-00-sa-cottons-on-to-fast-fashion [accessed 22 August 2017].

- Su, J. and Chang, A., 2018. Factors affecting college students’ brand loyalty toward fast fashion. International Journal of Retail & Distribution Management. 46(1), pp. 90-107.

- Taplin, I.M., 2014. Who is to blame? A re-examination of fast fashion after the 2013 factory disaster in Bangladesh. Critical Perspectives on International Business, 10(1/2), pp. 72-83.

- Theunissen, G., 2020. ‘Made in SA, not China.’ Why Foschini, Mr Price and Truworths now want local clothes. Business Insider SA, 15 October. [online] Available at: https://www.businessinsider.co.za/foschini-mr-price-truworths-are-moving-away-from-chinese-imports-2020-10 [accessed 27 February 2021].

- Uriarte Elizaga, L., 2016. The contrast of fast fashion giants Zara, H&M and Uniqlo. Unpublished Master’s in Industrial Engineering, National Dong Hwa University, Taiwan.

- Ursachi, G., Horodnic, I.A. and Zait, A., 2015. How reliable are measurement scales? External factors with indirect influence on reliability estimators. Procedia Economics and Finance, 20, pp. 679-686.

- Van Zyl, G. and Matswalela, K., 2016. A comparative analysis of the level of competitiveness of the South African Clothing and Textile Industry. Journal of Economic and Financial Sciences, 9(2), pp. 370-391.

- White, G., 2017. Quick response inputs and outcomes in the apparel industry: an example from a South African retailer. Unpublished Master’s dissertation, University of Cape Town, South Africa.

- Wong, C.Y., Boon-itt, S. and Wong, C.W.Y., 2011. The contingency effects of environmental uncertainty on the relationship between supply chain integration and operational performance. Journal of Operations Management, 29, pp. 604–615

- Yu, J.P., Chang, J., Wong, Y.H. and Moon, K.-L., 2012. Fast Fabric: Development and Production Practices of Dominant Fast Fashion Retailers. Research Journal of Textile and Apparel, 16(3), pp. 1-17.

- Yu, W. and Ramanathan, R., 2012. Managing strategic business relationships in retail operations: evidence from China. Asia Pacific Journal of Marketing and Logistics, 24(3), pp. 372-393.

- Zheng, C. S., 2010. Leanness and Agility: Connection or Contradiction? Unpublished M.Sc. dissertation, Tilburg University, Netherlands.

Article Rights and License

© 2021 The Authors. Published by Sprint Investify. ISSN 2359-7712. This article is licensed under a Creative Commons Attribution 4.0 International License.